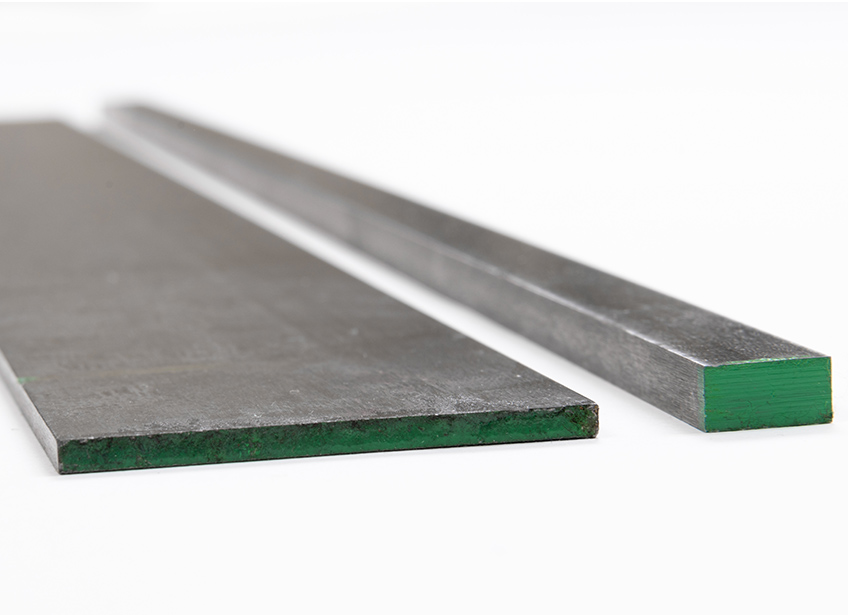

Precision Ground Rectangles & Squares On Size & Oversized

Tool Steel Alloy

Tool Steel Alloy| Grade | Description |

|---|---|

| A-2 | Air-hardening steel. Replaces O-1 when safer hardening, better dimensional stability and increased wear-resistance are required. Most widely used in the A series. |

| D-2 | High carbon and high chrome. Ideal grade for maximum production runs. Superior machinability. Excellent wear-resistance, high compressive strength, and deep hardening properties. Most widely used in the D series. |

| M-2 | General purpose high speed steel. Most widely used in the M series. |

| O-1 | Oil Hardening. Easy to machine. Good abrasion resistance. Most widely used in O series. |

| S-7 | Shock resistant tool steel. Used in applications that require high toughness and resistance. Used for moderately elevated temperature service. |

| W-1 | Water hardening tool steel. Water quenched to achieve desired hardness. Most widely used in W series. |

| Grade | Description |

|---|---|

| 4140 | Medium carbon steel that is widely used for general purposes. Good hardenability, strength, toughness, wear resistance, and ductility. |